Water Transfer Pump Suppliers: A Comprehensive Guide for 2025

Introduction

Water is an essential resource for households, industries, and agriculture. The ability to move it efficiently across distances, elevations, or storage systems is made possible through water transfer pumps. These devices are indispensable for managing water in scenarios ranging from irrigation and firefighting to municipal water distribution and industrial cooling systems.

As demand grows for better water infrastructure across both developed and emerging markets, water transfer pump suppliers play an increasingly critical role. Whether you’re operating a commercial facility, managing a farm, or overseeing municipal services, finding the right supplier is vital to ensure Water Transfer Pump Supplier 2025 efficiency, reliability, and long-term cost savings.

This article explores the current landscape of water transfer pump suppliers in 2025. Water Transfer Pump Supplier 2025 We’ll discuss types of pumps, key applications, factors to consider when selecting a supplier, market trends, and review some of the top suppliers operating globally Water Transfer Pump Supplier 2025 and regionally.

What Is a Water Transfer Pump?

A water transfer pump is a mechanical device that moves water from Water Transfer Pump Supplier 2025 one Water Transfer Pump Supplier 2025 location to another. Unlike centrifugal or submersible pumps designed for specific conditions, water transfer pumps are typically Water Transfer Pump Supplier 2025 used to transport large volumes of water quickly, regardless of source.

Key Functions:

- Moving water between reservoirs or tanks

- Irrigating fields

- Dewatering flooded areas

- Filling or draining swimming pools

- Transferring water in construction or mining sites

Types of Water Transfer Pumps

1. Centrifugal Pumps

- Most common in industrial and municipal Water Transfer Pump Supplier 2025 use.

- Ideal for clean water with low viscosity.

- Works well in open systems and long-distance transfers.

2. Positive Displacement Pumps

- Includes diaphragm, gear, and peristaltic Water Transfer Pump Supplier 2025 pumps.

- Suitable for viscous or slurry-type liquids.

- Offers precise flow control.

3. Submersible Transfer Pumps

- Fully submerged in water.

- Ideal for wells, drainage, and sump applications Water Transfer Pump Supplier 2025.

4. Engine-Driven Transfer Pumps

- Powered by petrol or diesel engines.

- Perfect for remote areas without electricity.

- Common in agriculture and emergency flood Water Transfer Pump Supplier 2025 response.

5. Solar-Powered Transfer Pumps

- Use solar energy, reducing operational costs.

- Popular in sustainable agriculture and off-grid applications Water Transfer Pump Supplier 2025.

Applications of Water Transfer Pumps

Water transfer pumps serve a wide range of applications across industries:

| Sector | Application |

|---|---|

| Agriculture | Irrigation, water delivery to fields, greenhouse watering |

| Construction | Site dewatering, concrete batching |

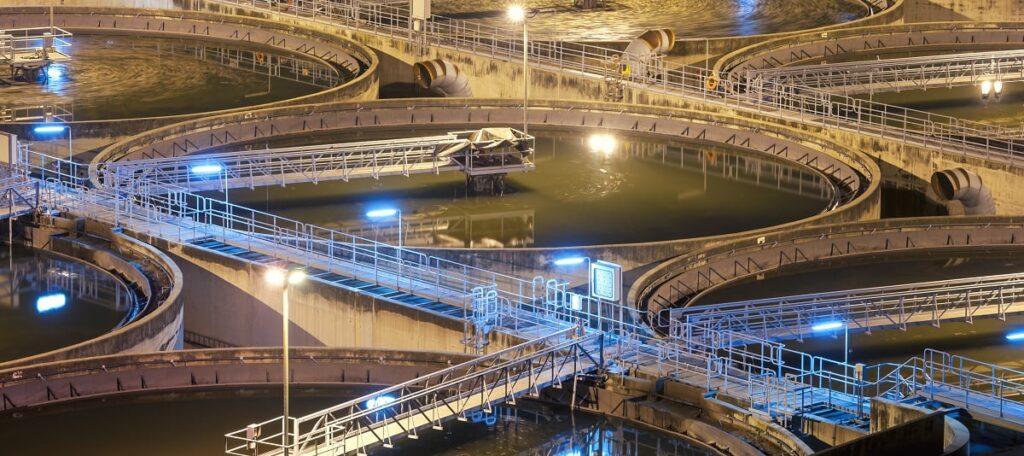

| Municipalities | Water supply systems, sewer and stormwater management |

| Mining | Slurry handling, water drainage |

| Residential | Well water delivery, garden watering |

| Disaster Management | Emergency flood control, firefighting |

Key Features to Look for in a Water Transfer Pump Supplier

1. Range of Products

A reliable supplier should offer a variety of pump types, sizes, Water Transfer Pump Supplier 2025 and capacities to meet diverse application needs.

2. Certifications and Standards

Ensure compliance with global quality standards such Water Transfer Pump Supplier 2025 as:

- ISO 9001: Quality Management

- CE Certification (for EU markets)

- ANSI, API, or NSF (for specific industrial applications)

3. After-Sales Support

Look for suppliers offering:

- Installation services

- Maintenance contracts

- Availability of spare parts

- 24/7 emergency support

4. Technical Expertise

Suppliers with an experienced engineering team can Water Transfer Pump Supplier 2025 offer better customization, sizing, and troubleshooting advice.

5. Global or Regional Reach

A local presence ensures faster response times, better service, and lower shipping costs.

Top Water Transfer Pump Suppliers (Global & Regional)

Here’s a list of some of the most reputable and widely used water transfer Water Transfer Pump Supplier 2025 pump suppliers in 2025:

1. Grundfos (Denmark)

- Strengths: Sustainability, energy-efficient designs, smart pump systems

- Popular Models: CR, NB, and CM series

- Sectors Served: Commercial buildings, agriculture, and utilities

- Notable Projects: Urban water supply projects in Europe and Asia

2. Xylem (USA) – Including Brands like Flygt & Goulds

- Strengths: High-capacity transfer pumps, smart monitoring Water Transfer Pump Supplier 2025 systems

- Popular Models: Godwin Dri-Prime, Flygt submersibles

- Industries: Mining, disaster response, wastewater

- Global Reach: Strong presence in North America, Middle East, and Africa

3. KSB (Germany)

- Known For: Durable and efficient centrifugal pumps

- Popular Series: Etanorm, MegaCPK

- Clients: Industrial and municipal customers worldwide

- Tech Innovations: Integration with IoT and predictive maintenance Water Transfer Pump Supplier 2025 software

4. Wilo (Germany)

- Specialization: Smart pump solutions for residential and Water Transfer Pump Supplier 2025 commercial use

- Strengths: Compact designs, quiet operation, mobile app integration

- Emerging Markets: Rapidly expanding in the Middle East and Southeast Asia

5. Ebara (Japan)

- Strengths: High-pressure transfer, corrosion-resistant designs

- Applications: Power plants, chemical transfer, seawater movement

- Environmental Focus: Eco-friendly pump systems with lower CO₂ footprints

6. Franklin Electric (USA)

- Specialty: Submersible and surface water transfer pumps

- Ideal For: Agriculture, residential wells, and irrigation

- Distribution: Strong supply chain in Latin America and Africa

7. Tsurumi Pump (Japan)

- Key Feature: Heavy-duty submersible water transfer pumps

- Best Use: Dewatering in construction and mining

- Durability: Built for abrasive environments

8. Regional Suppliers – Middle East & Africa

- Companies: Al Wathba Pumps (UAE), SafeRain Pumps (KSA), Davis & Shirtliff (Kenya)

- Focus: Agricultural and municipal water transfer

- Advantage: Local availability and installation services

Trends Shaping the Water Transfer Pump Market in 2025

1. Smart Pumping Systems

Many suppliers now offer pumps with embedded sensors, enabling:

- Remote monitoring

- Predictive maintenance

- Performance optimization via mobile apps

2. Green Technologies

Energy-efficient motors, solar-powered systems, and variable speed drives (VFDs) are helping reduce operational costs and carbon footprints.

3. Automation & IoT Integration

Pump systems now connect with SCADA, IoT platforms, and AI algorithms to:

- Detect leaks

- Adjust pressure based on demand

- Improve system uptime

4. Portable Water Transfer Solutions

Compact, portable pumps are in high demand for emergency response, rural irrigation, and off-grid locations.

5. Custom-Built Solutions

Industries like oil & gas, mining, and wastewater treatment increasingly demand custom-engineered pump packages designed for harsh or unique environments.

Challenges in the Industry

Despite advancements, the water transfer pump industry still faces some key challenges:

- Power Availability: In remote or off-grid areas, electricity for pumps remains a challenge.

- Maintenance Gaps: In some regions, lack of technical expertise leads to operational downtime.

- Cost Barriers: High upfront costs of smart and solar-powered pumps may deter small-scale users.

- Water Quality: Dirty or sediment-laden water can damage pumps not designed for such conditions.

How to Choose the Right Water Transfer Pump Supplier

Here’s a practical checklist:

| Criteria | What to Look For |

|---|---|

| Reputation | Years of experience, customer reviews |

| Product Range | Availability of various pump types |

| Support Services | Maintenance, training, spare parts availability |

| Technology | Smart controls, energy efficiency, monitoring tools |

| Customization | Ability to design pump systems for specific needs |

| Warranty & Certifications | At least 2–5 years warranty, ISO or CE compliance |

| Local Presence | Offices or service centers near your location |

Future Outlook

The global market for water transfer pumps is projected to grow at a CAGR of 6–8% through 2030, driven by:

- Urbanization

- Climate change and drought mitigation

- Smart infrastructure and sustainable farming

- Post-pandemic recovery in infrastructure spending

Governments and private sectors are investing more in resilient, sustainable water management, placing reliable water transfer pump suppliers at the forefront of change.

Conclusion

Water transfer pumps are essential tools in the global push for water sustainability, agriculture, disaster management, and industrial efficiency. As 2025 sees greater technological advancement and environmental consciousness, the choice of pump supplier becomes even more strategic.

Whether you are sourcing pumps for municipal water delivery or irrigation on a farm, partnering with a certified, technically capable, and service-oriented supplier is key. With the right water transfer pump and a trusted supplier, you ensure not just water flow—but reliability, efficiency, and long-term cost savings.